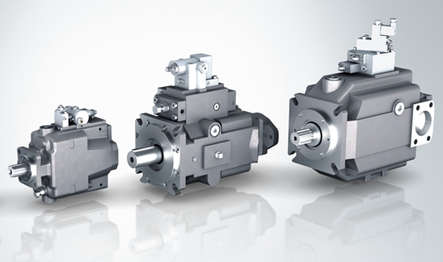

Hydraulic pumps play a crucial role in various industries, from construction and manufacturing to agriculture and transportation. These powerful machines are essential for converting mechanical power into hydraulic energy, enabling the smooth operation of a wide range of equipment.

To keep your Hydraulic Pumps running efficiently and extend their lifespan, proper maintenance is key.

Explore five easy ways to maintain your hydraulic pumps like a pro:

-

Regular Inspection is the Key

Inspecting your hydraulic pumps regularly is the first step in ensuring their optimal performance. Look for any signs of leaks, unusual noises, or changes in performance. Check the fluid levels and quality, as contaminated or insufficient hydraulic fluid can lead to pump failure.

Addressing minor issues early can prevent major breakdowns and save you both time and money in the long run.

-

Keep It Clean

Maintaining a clean environment around your hydraulic pumps is essential. Dust, dirt, and debris can find their way into the system, causing damage to internal components. Use compressed air or a vacuum to remove any contaminants from the pump’s exterior.

Additionally, make sure to keep the hydraulic fluid clean and free from impurities by using high-quality filters and changing the fluid at recommended intervals.

-

Lubrication is Vital

Proper lubrication is critical for the smooth operation of hydraulic pumps. Check the manufacturer’s guidelines to ensure you’re using the correct type of lubricant and applying it at the recommended intervals. Insufficient lubrication can lead to increased friction, wear, and even pump failure.

Remember to replace any worn-out parts and seals during routine maintenance to avoid leaks and ensure the pump’s longevity.

-

Monitor Operating Conditions

Monitoring the operating conditions of your hydraulic pumps can help you detect potential issues early on. Keep an eye on the temperature and pressure levels regularly. Unusual spikes or drops in these parameters can indicate underlying problems.

If your equipment is frequently operating at extreme conditions, consider installing additional cooling or heating systems to maintain a stable environment for your hydraulic pumps.

-

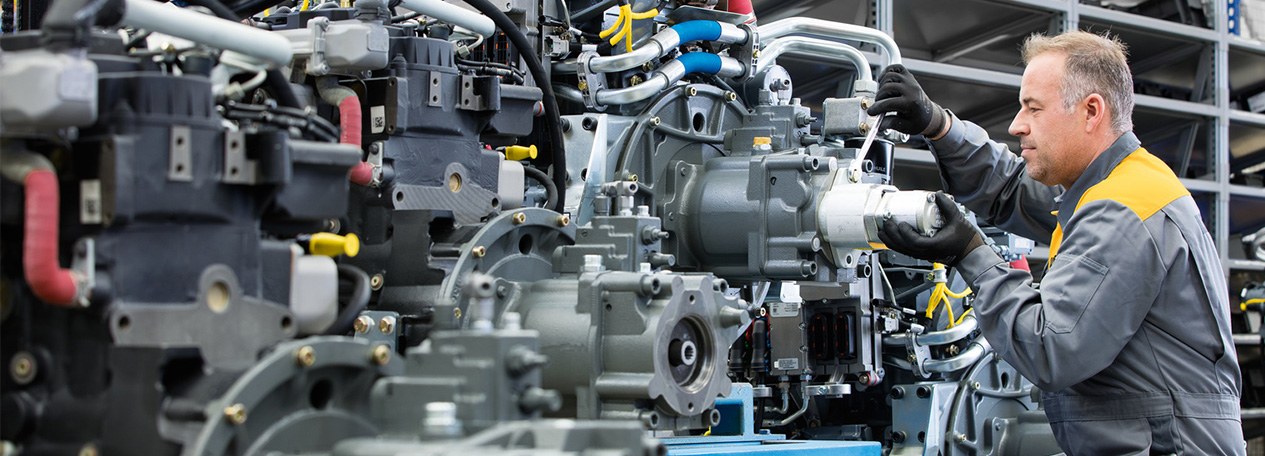

Train Your Operators

Often overlooked, proper training for your equipment operators is essential for maintaining hydraulic pumps effectively. Make sure your staff understands the importance of regular maintenance and knows how to identify warning signs.

Teach them the correct procedures for handling hydraulic systems, including startup and shutdown routines, to avoid unnecessary strain on the pumps.

Conclusion

Taking care of your hydraulic pumps doesn’t have to be a complex task. By following these five easy ways, you can maintain your hydraulic pumps like a pro!

Regular inspections, cleanliness, lubrication, monitoring, and well-trained operators will ensure your pumps operate smoothly, efficiently, and have a longer lifespan. Remember, preventative maintenance is always more cost-effective than dealing with unexpected breakdowns.

Investing time and effort in maintaining your hydraulic pumps will not only save you money but also boost productivity and minimise downtime in the long run.

So, take charge of your hydraulic pump maintenance today and enjoy the benefits of reliable and efficient equipment for years to come.

Source – https://hydraulic-filter.blogspot.com/2023/08/5-easy-ways-to-maintain-your-hydraulic.html