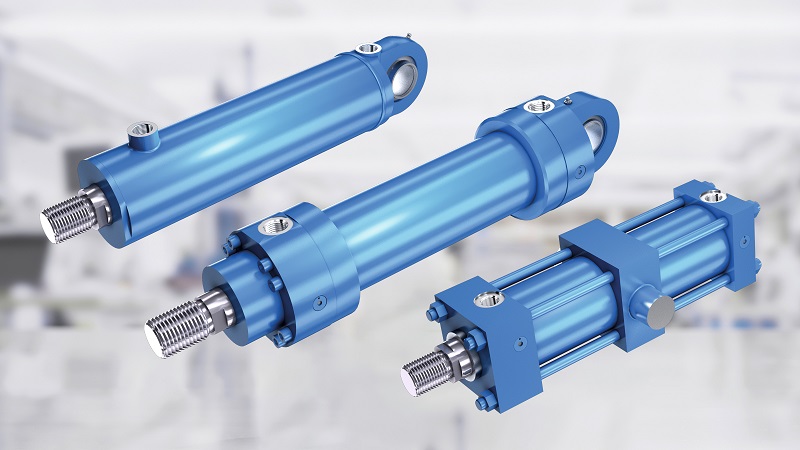

Welcome to the world of hydraulic systems! Whether you’re in construction, manufacturing, or any field that relies on heavy machinery, knowing the ins and outs of hydraulic cylinder repair is vital.

These cylinders are the workhorses behind the powerful, controlled movements of machinery. However, they’re not immune to wear and tear.

In this blog, we’ll guide you through the professional process of repairing hydraulic cylinders, ensuring your equipment operates at peak performance for longer periods.

So, let’s dive into this essential maintenance task and ensure your machinery continues to serve you efficiently and reliably.

Overview of Hydraulic Cylinder Repair Process

Maintaining and repairing hydraulic cylinders is paramount to ensuring that machinery runs efficiently and lasts longer.

A professional hydraulic cylinder repair process not only helps in restoring the cylinder’s optimal performance but also prevents future failures, ultimately saving time and resources.

Importance of Proper Repair

Proper hydraulic cylinder repair is crucial for several reasons. Firstly, it ensures that the hydraulic system operates at its peak, providing the necessary power for machinery.

Secondly, it significantly reduces the likelihood of unexpected breakdowns, which can be costly and disrupt operations. Proper repair also extends the lifespan of the cylinder and the hydraulic system, making it a cost-effective solution in the long run.

Common Issues with Hydraulic Cylinders

Several issues can affect hydraulic cylinders, requiring professional attention. These include:

– Leaks in the seals, which can lead to loss of pressure and fluid.

– Wear and tear on the piston rod and cylinder bore, affecting the system’s efficiency.

– Contamination of hydraulic fluid, which can cause damage to internal components.

– Corrosion of metal parts, especially in harsh environments.

Understanding these common issues is the first step in addressing and preventing them through professional repair and maintenance.

Initial Inspection of Hydraulic Cylinder

Before diving into the repair process, an initial inspection is essential to accurately assess the condition of the hydraulic cylinder and identify any issues.

Visual Inspection

A thorough visual inspection is the first step in assessing a hydraulic cylinder’s condition. This examination involves checking for visible signs of wear, damage, or corrosion on the cylinder body, piston rod, and seals. It’s also crucial to look for any misalignment that could indicate potential internal problems.

Testing for Leaks

After the visual inspection, testing for leaks is a vital step. Leaks can occur both internally, where fluid passes from the high-pressure side to the low-pressure side without making it past the piston, and externally, where fluid escapes the cylinder altogether.

Using specialised equipment, professionals can apply pressure to the system to identify any leaks, which are common indicators of seal failure or damage to the cylinder’s structure.

Addressing these leaks early on can prevent more significant issues down the line and ensure the hydraulic system operates efficiently.

Disassembly of Hydraulic Cylinder

Proper Disassembly Techniques

Disassembling a hydraulic cylinder is like solving a complex puzzle with care and precision. It begins by carefully relieving any pressure within the cylinder to ensure safety. Then, each component, including the cap, gland, piston, and rod, is methodically removed.

Special tools, such as spanner wrenches and cylinder disassembly benches, are employed to prevent damage to the components. The key is to maintain the integrity of each part, avoiding any unnecessary force that could cause harm.

This step requires patience and meticulous attention to detail, ensuring that each piece is catalogued for reassembly.

Inspection of Individual Components

Once disassembled, each part of the hydraulic cylinder undergoes a thorough inspection. This process is akin to a health check-up, seeking out any signs of wear, corrosion, or damage.

The rod and cylinder bore are scrutinised for scratches or pitting, which could impair the cylinder’s performance.

Seals and O-rings are checked for wear and elasticity, as these are often the first components to show signs of failure. This detailed inspection helps to identify any hidden issues that might compromise the cylinder’s efficiency, ensuring that only perfectly functioning parts are reassembled.

Replacement of Damaged Parts and Seals

Identifying Damaged Parts

Identifying damaged parts is a critical step in the hydraulic cylinder repair process. Based on the inspection, components that are beyond repair or show significant wear are earmarked for replacement.

Common culprits include bent rods, scored cylinders, and worn seals. The goal is to identify any parts that could negatively impact the performance or lifespan of the hydraulic cylinder, ensuring that the repaired cylinder operates as efficiently as a new one.

Selecting Quality Replacement Seals

When it comes to seals, opting for high-quality replacements is non-negotiable.

Seals are the lifeline of hydraulic cylinders, ensuring fluid doesn’t leak and maintaining pressure within the system.

Selecting the right seals involves matching the material and specifications to the cylinder’s requirements, considering factors such as temperature, pressure, and fluid type.

Quality seals offer resilience against wear and tear, ensuring the longevity and reliability of the hydraulic cylinder. Investing in superior-quality seals means fewer repairs down the line, saving time and money in the long run.

Cleaning and Preparation for Repair

Before diving into the thick of repairs, ensuring that the hydraulic cylinder and its components are clean is crucial.

This step is pivotal for two main reasons: it prevents contamination from interfering with the repair process and allows for a thorough inspection of all parts. The cleaning process involves removing any dirt, grime, and hydraulic fluid remnants using specialised cleaning agents and tools designed for hydraulic systems.

During the cleaning process, it’s essential to inspect each component for signs of wear, damage, or corrosion. Attention to detail is key, as even minor imperfections can lead to significant issues down the line.

Detailed documentation of any issues discovered during this process is crucial for deciding whether to repair or replace specific parts.

Reassembly of Hydraulic Cylinder

The reassembly process is where precision and expertise come into play. After cleaning and inspection, ensuring that each part of the hydraulic cylinder is correctly reassembled ensures the unit operates efficiently and safely.

Assembly of Components

Reassembling the hydraulic cylinder involves putting back together the cleaned and inspected or new components in their correct order.

Start by carefully installing the piston and seals onto the piston rod, making sure that all seals are correctly positioned to prevent leaks. Next, the piston rod assembly is inserted into the cylinder barrel.

It’s essential to lubricate all moving parts and seals with a thin layer of hydraulic oil during assembly to ensure smooth operation and prevent initial wear.

Torque Specifications and Guidelines

Adhering to proper torque specifications is critical during the reassembly process. Each component of the hydraulic cylinder, especially the bolts and nuts, needs to be tightened to the manufacturer’s recommended torque values. These specifications ensure that components are sufficiently tightened without being overstressed, which could lead to premature failure.

Using a calibrated torque wrench is the best practice, as it provides the precision required for these specifications. Additionally, it’s important to follow any sequence guidelines provided by the manufacturer for tightening bolts.

This sequence is designed to ensure an even distribution of pressure and prevent misalignment of the cylinder components. Once the cylinder is fully reassembled, a final inspection and test should be conducted to ensure it meets all operational standards.

Testing and Final Adjustments

After the meticulous process of disassembly, cleaning, and replacing all necessary parts, the hydraulic cylinder is almost set to go back into action. However, before it can be declared fully functional, it needs to go through a series of tests and adjustments to ensure it operates safely and efficiently.

Pressure Testing

The first step in this final phase is pressure testing. This is crucial to verify that the cylinder can handle the operational pressures it will face in the field. During pressure testing, the cylinder is subjected to pressures that match or exceed its normal operating pressures.

This test helps to identify any leaks or weaknesses in the seals or the cylinder structure. It’s like giving the cylinder a trial by fire, ensuring it’s tough enough to handle its tasks without failure.

Adjusting Hydraulic Cylinder Settings

Once the cylinder passes the pressure test with flying colours, it’s time to adjust its settings for optimal performance. This could include fine-tuning the piston’s speed, the force it exerts, and the fluid flow rate.

These adjustments ensure the cylinder operates smoothly within the specific requirements of the hydraulic system it’s a part of. Think of it as calibrating the instrument to play the perfect tune.

Final Inspection

The final inspection is the last checkpoint before the hydraulic cylinder can be reinstalled.

This meticulous examination includes checking for any signs of leaks, ensuring all parts are properly tightened, and verifying that all repairs meet the expected quality standards. It’s the final nod of approval that says, “Yes, this cylinder is ready to go back to work.”

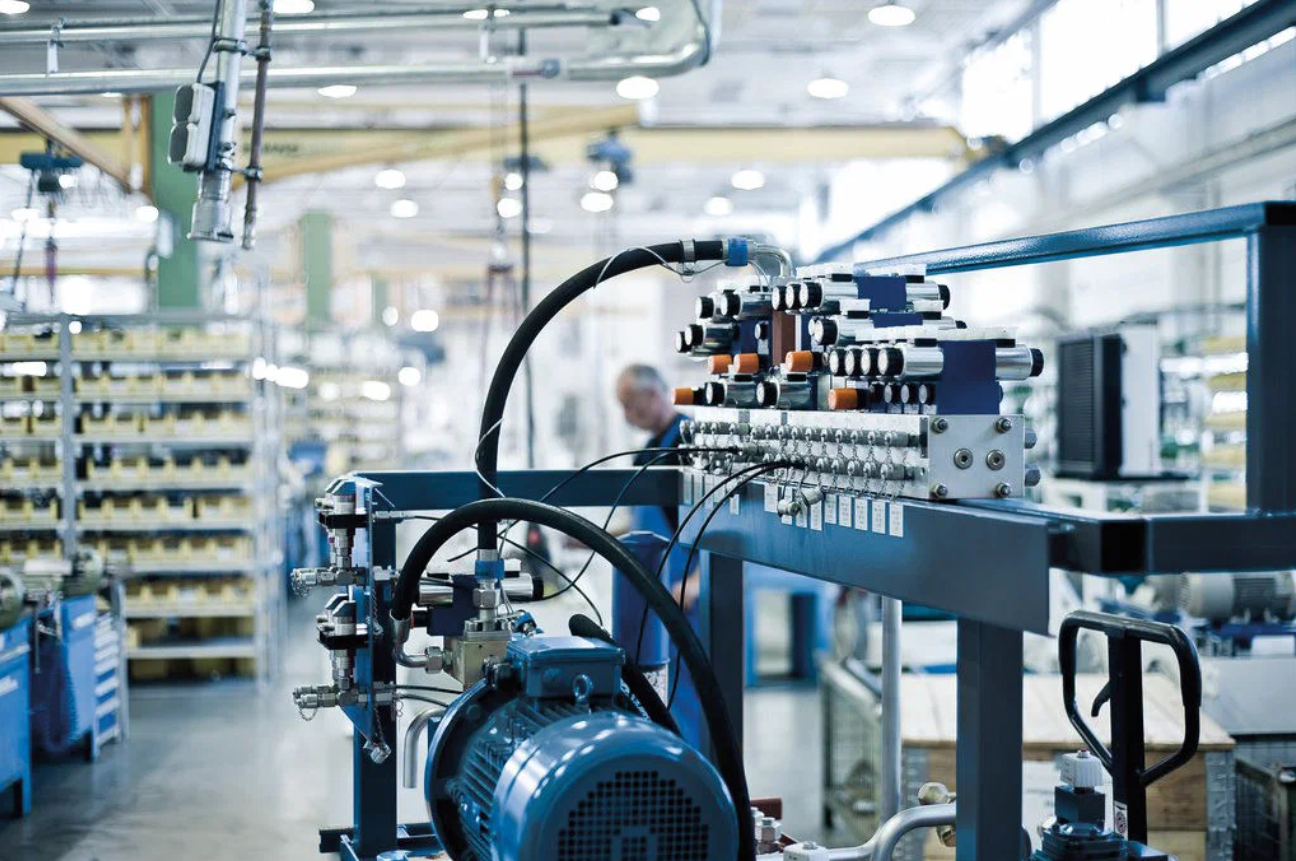

Tools Required for Professional Hydraulic Cylinder Repair

A professional hydraulic cylinder repair is no small feat and requires an array of special tools to get the job done right. The right tools not only make the repair process more efficient but also ensure the longevity and reliability of the cylinder post-repair.

List of Essential Tools

– Wrench sets: For loosening and tightening bolts and nuts.

– Seal installation tools: These are used to properly install seals without damage.

– Hydraulic piston rod clamp: To secure the rod without causing surface damage.

– Cylinder hone: This is used to refinish the interior surface of the cylinder.

– Measuring tools (micrometres, callipers): To precisely measure parts for wear and fit.

Having these tools at hand is crucial for tackling the various steps involved in repairing a hydraulic cylinder, from disassembly to reassembly.

Importance of Using Proper Tools

Utilising the proper tools is not just about making the repair process smoother; it’s about ensuring the repair is done to a professional standard.

The right tools help prevent damage to parts during disassembly and reassembly, ensure accurate measurement and fit of replacement parts, and ultimately lead to a more reliable and longer-lasting repair.

In the world of hydraulic cylinder repair, the quality of the tools is as important as the skill of the technician using them.

Conclusion

As we’ve journeyed through the meticulous process of professional hydraulic cylinder repair, it’s clear that maintaining the integrity and functionality of these essential components is not a task to be taken lightly.

Remember, proper maintenance doesn’t just prolong the life of your hydraulic cylinders; it also enhances the performance and reliability of your entire hydraulic system.

Understanding the professional hydraulic cylinder repair process empowers you to make informed decisions about the care and maintenance of your hydraulic systems.