When it comes to hydraulic systems, the quality of solenoid valves is paramount to ensure optimal performance and reliability. Selecting the best quality hydraulic solenoid valves is essential for the efficient operation of hydraulic machinery and equipment.

In this comprehensive guide, we’ll explore the key factors to consider when choosing hydraulic solenoid valves of the highest quality, empowering you to make informed decisions for your hydraulic system needs.

Understanding the Role of Hydraulic Solenoid Valves

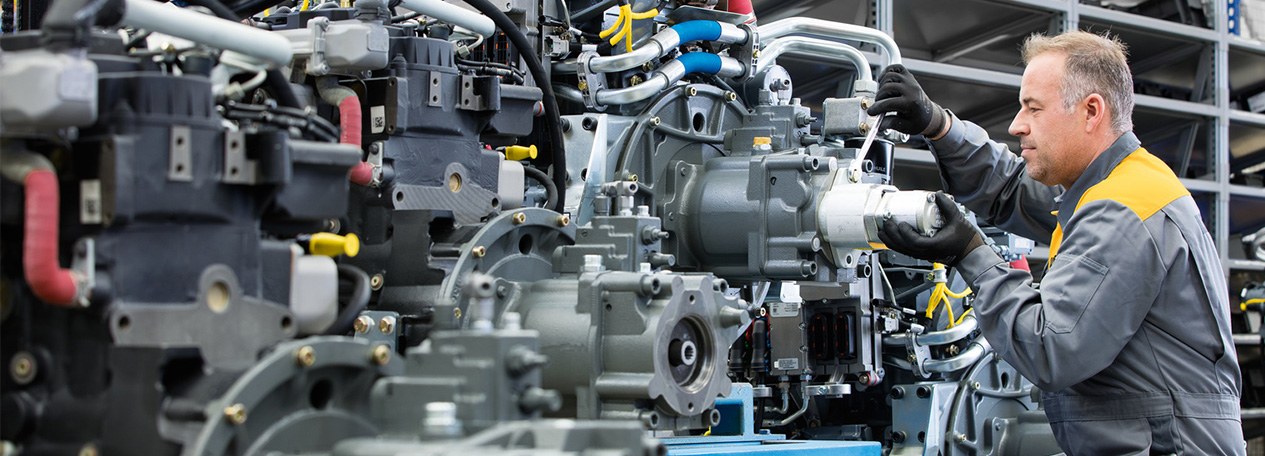

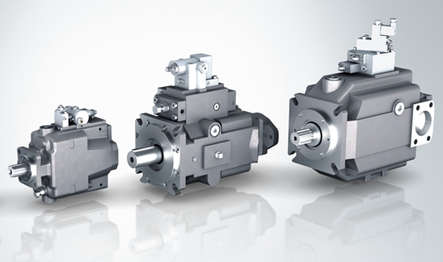

Before delving into the selection process, it’s crucial to understand the significance of hydraulic solenoid valves in hydraulic systems. These valves control the flow of hydraulic fluid within a system, regulating the direction, pressure, and volume of the fluid to execute specific functions such as actuation, stopping, and diverting of fluid flow. Quality solenoid valves are essential for ensuring precise and efficient control within hydraulic systems.

Reliability and Durability

One of the primary considerations when choosing hydraulic solenoid valves is the reliability and durability of the components. Look for valves constructed from high-quality materials such as stainless steel or brass, as well as those that are designed to withstand the demanding conditions of hydraulic applications. Valves with robust construction and durability are crucial for long-term performance and minimal maintenance requirements.

Compatibility and Application-Specific Requirements

Selecting the best quality hydraulic solenoid valves involves assessing their compatibility with the specific hydraulic system and application requirements. Consider factors such as pressure ratings, flow capacity, temperature range, and compatibility with different hydraulic fluids. Ensuring that the valves are tailored to meet the unique demands of the system and application is essential for achieving optimal performance and longevity.

Precision and Response Time

The precision and response time of hydraulic solenoid valves significantly influence the effectiveness of hydraulic systems. High-quality valves exhibit precise control over fluid flow and demonstrate swift response times, enabling efficient and accurate operation. Evaluate the responsiveness and precision of the valves to ensure that they meet the performance standards required for the intended application.

Sealing and Leakage Prevention

Quality hydraulic solenoid valves must incorporate effective sealing mechanisms to prevent fluid leakage and ensure a reliable seal under varying pressures and operating conditions. Valves featuring resilient seals, are crucial for maintaining tight seals and preventing potential leaks within the hydraulic system. Leakage prevention is essential for the safety and efficiency of hydraulic operations.

Environmental Considerations and Resistance

In environments that are exposed to extreme temperatures, corrosive substances, or harsh operating conditions, the best quality hydraulic solenoid valves are designed to resist environmental challenges. Look for valves that are resistant to corrosion, chemicals, and contaminants, as well as those that can withstand temperature fluctuations and exposure to external elements. Environmental resistance contributes to the longevity and reliability of the valves.

Manufacturer Reputation and Standards Compliance

When sourcing hydraulic solenoid valves, consider the reputation and credibility of the manufacturers. Reputable manufacturers adhere to industry standards and certifications, ensuring that their valves meet strict quality and performance criteria. Research the reputation and track record of the manufacturers to identify reliable sources of hydraulic solenoid valves that prioritise quality and compliance with industry standards.

Cost-Effectiveness and Long-Term Value

While the focus is on quality, it’s also essential to consider the cost-effectiveness and long-term value offered by the hydraulic solenoid valves. Assess the overall lifecycle cost, including initial investment, maintenance requirements, and longevity, to determine the value proposition of the valves. Investing in high-quality valves that offer long-term reliability and performance can result in cost savings and operational efficiency over time.

Conclusion

In conclusion, choosing the best quality hydraulic solenoid valves is a critical decision that directly impacts the performance, reliability, and longevity of hydraulic systems. By considering factors such as reliability, compatibility, precision, sealing, environmental resistance, manufacturer reputation, and long-term value, you can identify and select valves that meet the highest standards of quality and performance.

Prioritising the selection of quality hydraulic solenoid valves is essential for optimising the functionality of hydraulic systems and ensuring consistent and reliable operation.