Welcome to our blog on the role of solenoid valves in hydraulic control systems! If you’ve ever wondered how fluid flow is regulated in hydraulic machinery or methods, you’re in the right place.

Solenoid valves are essential components that are crucial in controlling fluid flow rates and direction in hydraulic systems. In this blog, we will explore Hydraulic Solenoid Valves, the different types available, their importance in hydraulic control systems, typical applications, and more. So, let’s dive right in!

What are Solenoid Valves?

Solenoid valves are electromechanical devices that control the flow of fluids, such as liquids or gases, by opening or closing a valve. They consist of a coil, a plunger, and a valve body.

When an electric current is applied to the coil, it generates a magnetic field that attracts the plunger, causing it to move and open or close the valve. This mechanism allows solenoid valves to regulate the flow of fluids in Hydraulic Power Units.

Types of Solenoid Valves

A. 2-Way Solenoid Valves

2-way solenoid valves, also known as on/off solenoid valves, are the most basic type of solenoid valves. They have two ports, an inlet and an outlet, and control the on/off flow of fluids.

When the valve is energised, the plunger is pulled in, allowing fluid to flow from the inlet to the outlet. When the valve is de-energized, the plunger returns to its original position, blocking the fluid flow.

B. 3-Way Solenoid Valves

3-way solenoid valves have three ports: an inlet, outlet A, and outlet B. They are used to direct fluid flow between different pathways. When the valve is energised, fluid flows from the inlet to outlet A, and when de-energized, it flows from the inlet to outlet B.

These valves are commonly used in applications requiring switching between two fluid pathways.

C. 4-Way Solenoid Valves

4-way solenoid valves have four ports: an inlet, outlet A, outlet B, and an exhaust port. They are used to control fluid flow through multiple directions. When the valve is energised, fluid flows from the inlet to outlet A, and outlet B is connected to the exhaust port.

When de-energized, the connections are reversed, with fluid flowing from the inlet to outlet B and outlet A connected to the exhaust port. These valves are commonly used in applications that require the control of double-acting cylinders or motors.

Importance of Solenoid Valves in Hydraulic Control Systems

A. Precision Control

One of the primary reasons hydraulic solenoid valves are crucial is their ability to provide precise control over fluid flow rates.

By regulating the opening and closing of the valve, the flow rate can be accurately adjusted, ensuring the system operates at the desired levels. This precision control maintains system stability, accuracy, and overall performance.

B. Energy Efficiency

Solenoid valves also play a significantly role in conserving energy in hydraulic control systems. By controlling the flow of fluids, they can minimise unnecessary fluid flow, reducing energy consumption in the process.

For example, solenoid valves can be used to turn the flow on and off in applications where intermittent fluid flow is required, saving energy and reducing operational costs.

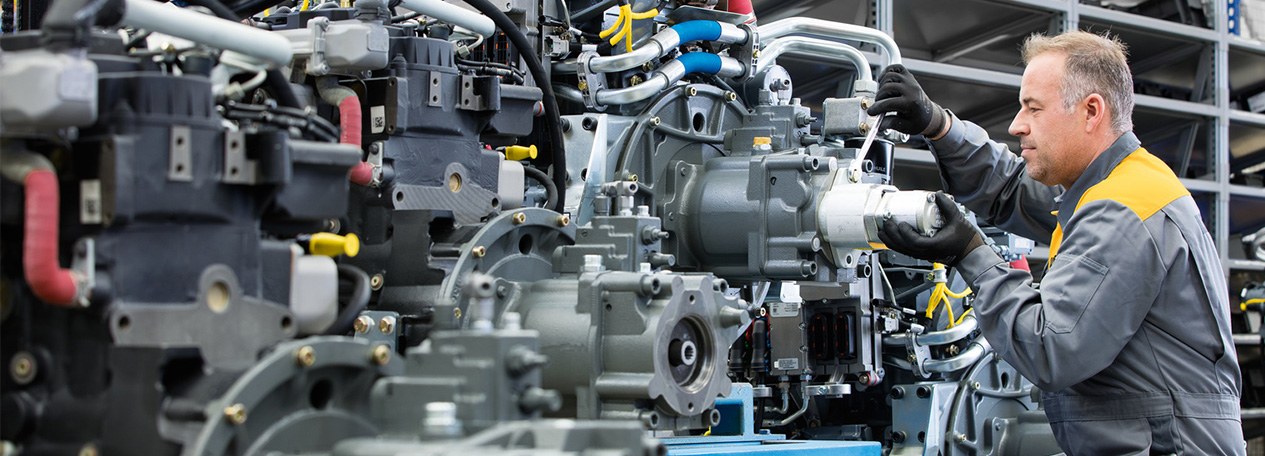

C. Reliability and Durability

In demanding hydraulic applications, reliability and durability are paramount. Solenoid valves are designed to withstand harsh conditions, making them suitable for various industries. They are often constructed with high-quality materials and undergo rigorous testing to ensure longevity and performance.

Additionally, industry standards and certifications assure their quality and reliability.

Common Applications of Solenoid Valves

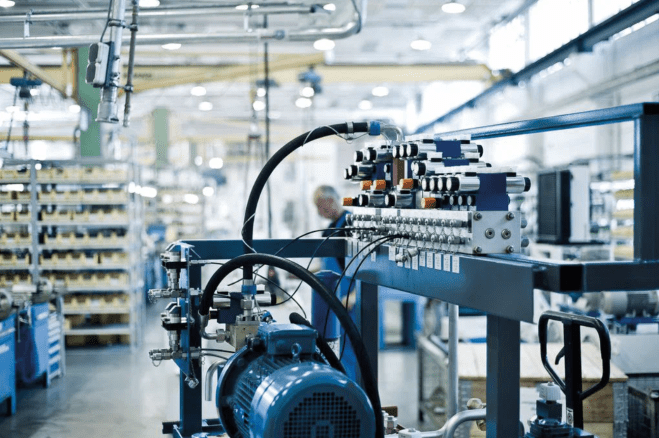

A. Manufacturing and Industrial Processes

Solenoid valves are extensively used in manufacturing and industrial processes involving hydraulic machinery. They control automated assembly lines, robotics, material handling systems, and other hydraulic equipment.

Solenoid valves contribute to efficient and reliable operations in these industries by precisely controlling fluid flow.

B. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on solenoid valves to regulate coolant flow, control water supply, or manage refrigerant flow. These valves enable efficient operation of HVAC systems, ensuring optimal temperature control and energy savings.

By controlling the flow of fluids in HVAC applications, solenoid valves contribute to a comfortable indoor environment while minimising energy consumption.

C. Medical Equipment

In the medical field, solenoid valves are essential components in various medical devices and equipment. Anaesthesia machines, fluid delivery systems, and other medical equipment require precise control over liquid flow.

Solenoid valves provide the necessary accuracy and reliability to ensure these devices’ safe and efficient operation, contributing to patient care and well-being.

Conclusion

Solenoid valves play a vital role in hydraulic control systems. Their precise ability to regulate fluid flow rates and direction makes them indispensable components in various industries and applications.

Whether in manufacturing processes, HVAC systems, or medical equipment, hydraulic solenoid valves enable efficient and reliable operation while contributing to energy savings and system stability. The importance of solenoid valves in hydraulic control systems cannot be overstated.

Source – https://www.apsense.com/article/the-role-of-solenoid-valves-in-hydraulic-control-systems.html