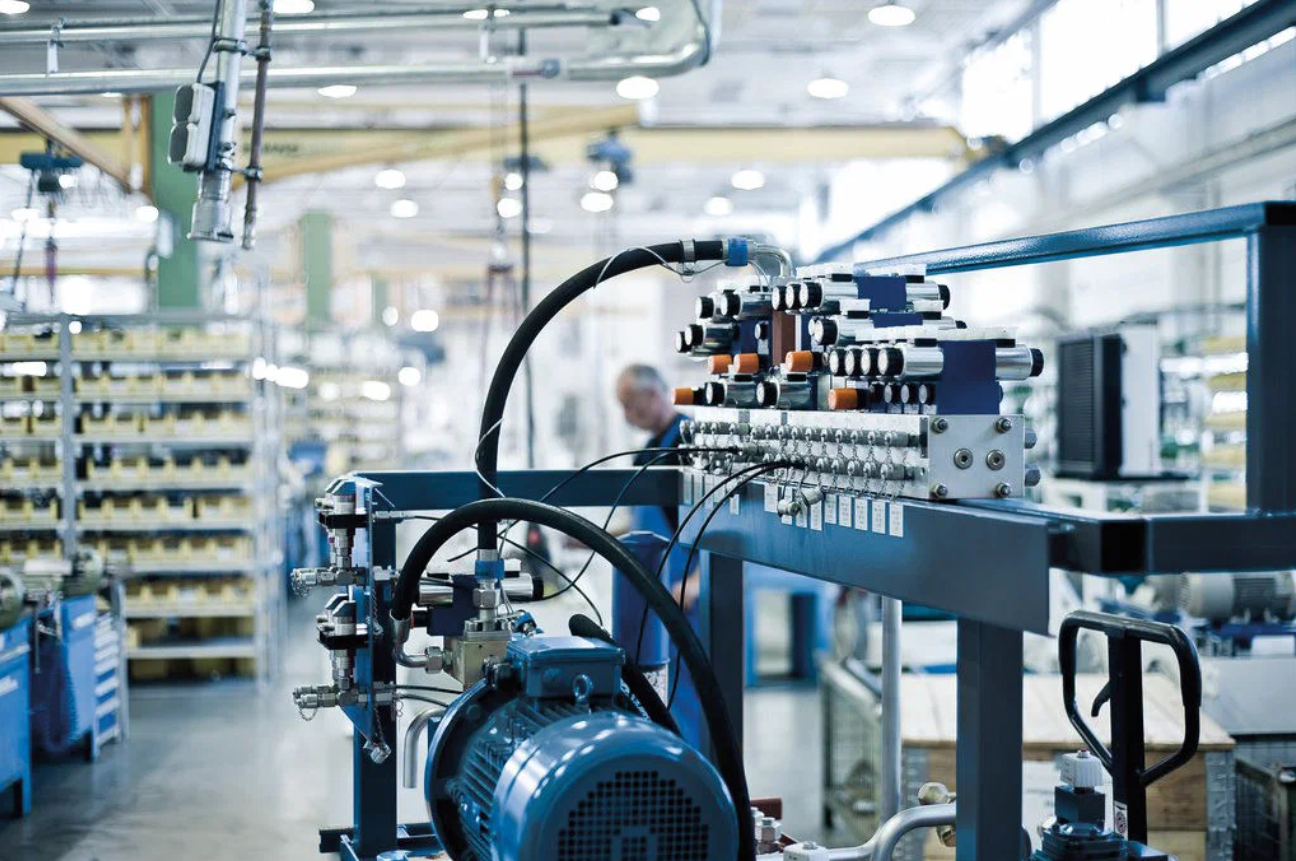

Hydraulic systems are essential components of various industries, providing the power needed to perform a wide range of tasks. At the heart of these systems are hydraulic pumps, which play a crucial role in generating the necessary fluid power.

In this blog, we’ll explore the top types of hydraulic pumps and their diverse applications, shedding light on their functionality and significance in different settings.

Understanding Hydraulic Pumps

Before delving into the specific types of hydraulic pumps, it’s important to understand their fundamental purpose. Hydraulic pumps are mechanical devices designed to generate flow and provide power to hydraulic systems.

They convert mechanical energy into hydraulic energy by pressurising hydraulic fluid. This pressurised fluid is then utilised to perform various tasks, making hydraulic pumps integral components of a wide array of applications.

Types of Hydraulic Pumps

1. Gear Pumps

Gear pumps are one of the most common types of hydraulic pumps. They operate using the intermeshing of gears to pump fluid.

With their simple design and ability to handle a wide range of viscosities, gear pumps are widely used in applications such as automotive power steering systems, forklifts, and construction equipment.

2. Vane Pumps

Vane pumps utilise vanes to push fluid through the pump. These pumps are known for their quiet operation and ability to handle low-to-medium pressure applications.

They find extensive use in industrial and mobile hydraulic systems, as well as in aerospace and automotive applications.

3. Piston Pumps

Piston pumps use reciprocating pistons to pressurise fluid. They are capable of handling high-pressure applications and are often used in heavy machinery, hydraulic presses, and other industrial equipment where high power density is required.

4. Radial Piston Pumps

Radial piston pumps consist of a set of pistons arranged radially around a drive shaft. These pumps are known for their high efficiency and are commonly employed in high-pressure hydraulic systems, including those used in plastic injection moulding machines, hydraulic presses, and marine equipment.

5. Axial Piston Pumps

Axial piston pumps feature pistons arranged in a circular array within a cylinder block. They are widely utilised in various hydraulic systems, including industrial machinery, agricultural equipment, and construction machinery, thanks to their ability to handle high pressure and provide efficient performance.

Applications of Hydraulic Pumps

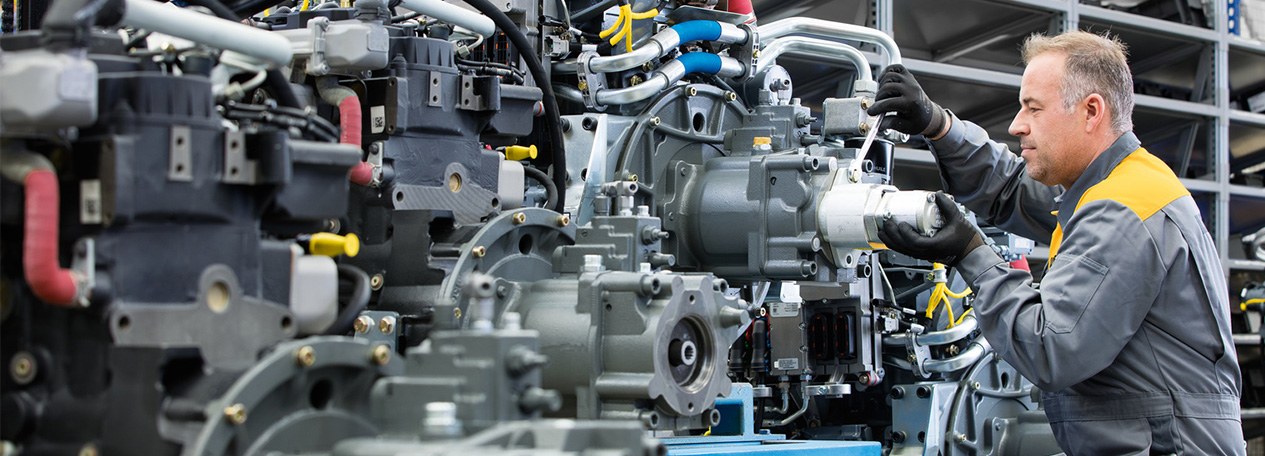

Industrial Machinery

In the industrial sector, hydraulic pumps play a critical role in powering heavy machinery such as presses, extruders, and injection moulding machines.

The high pressure and power density provided by piston pumps and radial piston pumps make them well-suited for these demanding applications.

Construction Equipment

Construction and earthmoving equipment rely heavily on hydraulic pumps to provide the power needed for tasks such as lifting, lowering, and manoeuvring heavy loads. Gear pumps and vane pumps are commonly used in hydraulic systems within excavators, dump trucks, and cranes.

Aerospace and Automotive Systems

Vane pumps are often employed in aerospace and automotive applications where quiet operation and efficient fluid handling are essential. These pumps are utilised in aircraft hydraulic systems, as well as in power steering and automatic transmission systems in automobiles.

Agriculture

In the agricultural sector, hydraulic pumps are integral to the operation of various equipment, including tractors, harvesters, and irrigation systems. Axial piston pumps are well-suited for these applications due to their ability to handle high pressure and provide reliable performance in demanding agricultural environments.

Marine Equipment

Radial piston pumps are commonly used in marine hydraulic systems to power steering, winches, and other equipment on ships and offshore platforms. Their high efficiency and ability to handle high-pressure applications make them ideal for these marine applications.

Conclusion

Hydraulic pumps are indispensable components of hydraulic systems across diverse industries. Understanding the various types of hydraulic pumps and their applications is crucial for selecting the right pump for specific tasks and ensuring efficient and reliable operation.

By exploring the functionality and significance of hydraulic pumps, we gain a deeper appreciation for the pivotal role they play in powering a wide range of machinery and equipment.

As we’ve seen, the versatility and performance of hydraulic pumps make them essential for achieving powerful and precise hydraulic operations across numerous applications. Whether in industrial settings, construction sites, aerospace and automotive systems, agriculture, or marine environments, hydraulic pumps continue to drive innovation and efficiency in hydraulic power systems.

Source URL: https://hydraulicpumpsau.blogspot.com/2024/04/top-types-of-hydraulic-pumps-and-their.html