In the realm of industrial machinery, efficiency and precision are paramount. One crucial component that plays a significant role in achieving optimal performance is the hydraulic solenoid valve. These valves are essential for controlling the flow of hydraulic fluid within machinery, influencing its overall functionality and reliability. In this blog post, we will explore how integrating the Best Quality Hydraulic Solenoid Valves can elevate machinery operations and drive productivity.

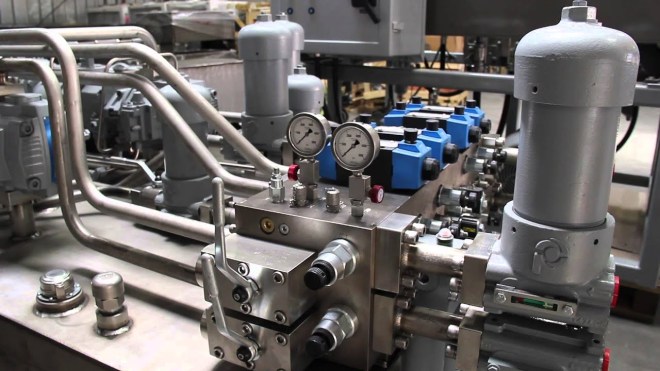

Understanding the Role of Hydraulic Solenoid Valves

At the core of hydraulic systems, solenoid valves act as the gateway for regulating fluid flow. By utilising electromagnetic principles, these valves can open or close to control the passage of hydraulic fluid, thereby dictating the movement and operation of various components within machinery. Their adaptability and responsiveness make them indispensable for a wide array of industrial applications.

Enhanced Performance and Precision

The integration of high-quality hydraulic solenoid valves translates to enhanced precision and performance. With precise control over fluid flow, machinery can operate with heightened accuracy and consistency, leading to improved production output and quality. The responsiveness of these valves enables machinery to swiftly adapt to changing operational requirements, ensuring seamless functionality.

Reliability and Durability

Reliable machinery operations are imperative for sustained productivity in industrial settings. The utilisation of the best quality hydraulic solenoid valves contributes to the overall reliability of machinery systems. These valves are engineered to withstand demanding conditions, exhibiting durability and longevity even in challenging environments. Their robust construction and design make them a dependable asset in industrial settings.

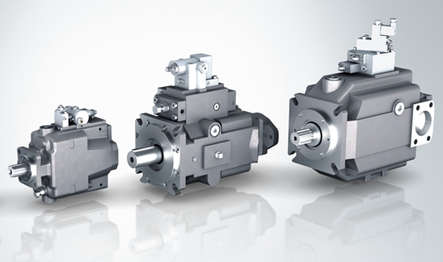

Customised Solutions for Diverse Applications

The best quality hydraulic solenoid valves offer a spectrum of customisation options, allowing for tailored solutions to suit diverse operational needs. Whether it involves specific fluid viscosities, pressure requirements, or operational temperatures, these valves can be configured to precisely match the demands of various machinery applications. This versatility enables optimised performance across a wide range of industrial processes.

Efficiency and Energy Conservation

Efficiency is a driving force in modern industrial operations. By utilising advanced hydraulic solenoid valves, machinery can operate with increased energy efficiency. These valves enable precise control over fluid flow, minimising unnecessary energy consumption and optimising the overall operational efficiency of machinery, ultimately leading to cost savings and reduced environmental impact.

Streamlined Maintenance and Operation

The incorporation of the best quality hydraulic solenoid valves facilitates streamlined maintenance and operation of machinery. Their robust design and reliability result in reduced downtime and maintenance requirements, allowing for uninterrupted production cycles. Additionally, the precise control afforded by these valves contributes to smoother machinery operation, reducing the likelihood of performance-related issues.

Adaptability to Industry 4.0

As industries embrace the era of digitalisation and automation, the integration of advanced hydraulic solenoid valves aligns with the principles of Industry 4.0. These valves can seamlessly integrate with smart machinery systems, enabling real-time monitoring, automation, and remote control capabilities. Such adaptability positions industrial operations at the forefront of technological innovation.

Conclusion

In conclusion, the integration of the best quality hydraulic solenoid valves represents a pivotal investment in optimising machinery operations. From precision and reliability to energy efficiency and adaptability, these valves serve as indispensable components for enhancing industrial performance. By leveraging the capabilities of advanced hydraulic solenoid valves, businesses can usher in a new era of operational excellence and productivity, ensuring a competitive edge in the modern industrial landscape.

By recognising the profound impact of hydraulic solenoid valves and embracing their potential, businesses can elevate their machinery operations to new heights, setting the stage for sustained growth and success.